Mining

Effectively remove buildup from mining equipment with ICEsonic dry ice blasters

Bitumen, tar and other buildup accumulate frequently preventing the mining equipment to operate properly. Dry ice blasting safely and efficiently removes residues from mining equipment. With the help of ICEsonic’s dry ice blasting system you will reduce production downtime, decrease risks of breakdowns and extend the operational life of your mining equipment. It doesn’t create secondary waste which results in reduced disposal costs and enables you to quickly and safely prepare for immediate painting and coating of your equipment. ICEsonic’s dry ice blasting system offers a new green cleaning technology utilizing a dry ice blasting with addition of an abrasive to remove stubborn buildup which cannot be eliminated with dry ice only. The ICEsonic DRY ICE + abrasive module is simply attached to all standard ICEsonic dry ice blasters and offers perfect solution for NDT testing.

Examples

· Compressors and pumps

· Extraction equipment

· Electric motors

· Generators

· Pressure, production and storage vessels

· Pipelines

Mining

Surface Preparation

Treat surfaces so they are clean, dry, oil free and ready for further treatment

ICEsonic’s dry ice blasting removes contaminants and build up without any change to the targeted surfaces. Dry ice blasting can be safely performed on a variety of surfaces. Treated surface will remain chemically clean, dry, oil free and ready for further treatment. Dry ice blasting leaves no residue and increases the efficiency of your work.

Recommended Products

Mining

General Equipment Cleaning

Increase the efficiency and lifespan of your equipment while saving time

Dry ice blasting is a fast and safe way to maintain all types of equipment. ICEsonic’s dry ice blasting is a completely dry cleaning process that is safe for all electrical components on your equipment. It allows you to clean in-place without cooldown or disassembly. Dry ice blasting is a non-abrasive, non-conductive cleaning method that is safe for the surface of your equipment. It will not create additional harmful waste.

Recommended Products

Mining

Operational Equipment Cleaning

Clean machines and electronics during operation to reduce downtime

Dry ice blasting is faster and more effective way of cleaning your operational equipment. ICEsonic dry ice blasting system enables you to remove the buildup from your equipment reducing the risk of breakdown without damaging surfaces. This cleaning method is non-abrasive, does not create secondary waste and is environmentally friendly. It improves preventative maintenance as well as inspection processes. Using ICEsonic dry ice blasting you will note reduction in production downtime and unplanned maintenance.

Recommended Products

Mining

Electrical Component Cleaning

Maintain high equipment efficiency and improve inspection processes

Dry ice blasting is a safe cleaning method for sensitive electrical components. It does not cause damage to the equipment due to dry ice’s non-abrasive properties. Dry ice blasting is possible when equipment is operational reducing production downtime. ICEsonic dry ice blasting system does not require additional chemicals and does not create secondary waste.

Recommended Products

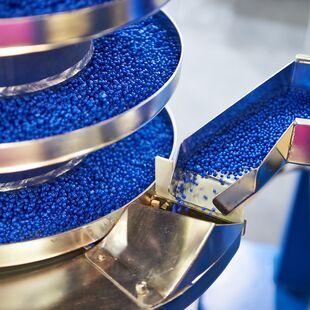

Dry Ice Blasting Benefits

Dry ice blasting is a safe and efficient cleaning method. This cleaning method allows immediate painting or coating upon dry ice blasting. ICEsonic dry ice blasting equipment is portable and can be used in-place.The process is non-abrasive, doesn’t produce secondary waste and is employee and environmentally safe. Abrasive modules by ICEsonic help clean the toughest surfaces by mixing abrasive material (e.g. glass beads) into your dry ice stream. The technology produces a clean, satin finish to a SA 2½ specification and is excellent for Non-Destructive Testing (NDT). This mix generates minimal dust pollution and abrasive usage.

· Non-abrasive

· Non-conductive

· No additional manual cleaning

· Reduction in downtime

· Doesn’t create secondary waste

· Employee and environmentally safe

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.