Food Processing and Packaging

Easily and quickly remove accumulated grease, harmful bacteria, adhesives, biofilms and other contaminants

Food industry has strict cleaning and disinfection programs to maintain hygiene standards. Risks of a poorly planned cleaning program include bacteria buildup from water blasting, salmonella from decaying food particles, quality issues, disposal costs, and liability. Dry ice is an approved medium by the EPA, USDA & FDA, and is non-toxic, non-hazardous and inhibits mold & bacteria growth. ICEsonic dry ice blasting is safe to use with food processing and packaging equipment, removes buildup like wax, glue, proteins, grease and other. Cleaning with dry ice does not release harmful gases into the atmosphere and does not generate secondary waste.

Examples

· Conveyor belts and chains

· Bread and pastry equipment

· Electrical motors and components

· Labelers and gluers

· Mills

· Slicing equipment

Food Processing and Packaging

General Equipment Cleaning

Increase the efficiency and lifespan of your equipment while saving time

Dry ice blasting is a fast and safe way to maintain all types of equipment. ICEsonic’s dry ice blasting is a completely dry cleaning process that is safe for all electrical components on your equipment. It allows you to clean in-place without cooldown or disassembly. Dry ice blasting is a non-abrasive, non-conductive cleaning method that is safe for the surface of your equipment. It will not create additional harmful waste.

Recommended Products

Food Processing and Packaging

Operational Equipment Cleaning

Clean machines and electronics during operation to reduce downtime

Dry ice blasting is faster and more effective way of cleaning your operational equipment. ICEsonic dry ice blasting system enables you to remove the buildup from your equipment reducing the risk of breakdown without damaging surfaces. This cleaning method is non-abrasive, does not create secondary waste and is environmentally friendly. It improves preventative maintenance as well as inspection processes. Using ICEsonic dry ice blasting you will note reduction in production downtime and unplanned maintenance.

Recommended Products

Food Processing and Packaging

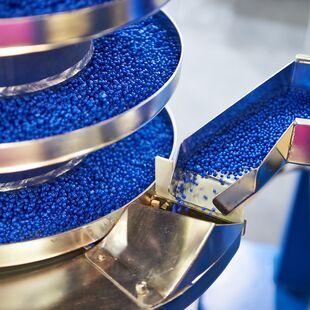

Plastic Injection Mold Cleaning

Increase the quality and lifespan of your plastic injection molds

ICEsonic dry ice blasting is a fast, effective and non-abrasive way of cleaning. Due to the dry ice blasting technology, mold cleaning can be performed on an operational mold press at operating temperatures. It is used to clean extruder screws, dies and casts, ovens, mixers, molds and other plastic injection equipment. Dry ice blasting will improve operational efficiency, quality parts and reduce costs.

Recommended Products

Dry Ice Blasting Benefits

Using ICEsonic dry ice blasting machines you are cleaning thoroughly all the contaminants from the designated surface. This cleaning method does not require chemicals and does not create additional waste. Due to properties of dry ice you are enabled to clean in-place while the equipment is still operational.

· No additional residue

· Chemical free

· Employee and environmentally safe

· Non-abrasive

· Reduction in downtime

· Reduction in repair costs

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.