Foundry

Reduce scrap rates and prolong the lifespan of your molds, core boxes and tooling

ICEsonic dry ice blasting provides economic and quick cleaning solution for permanent molds, core boxes, die casting tooling and additional equipment. Dry ice blasting reduces downtime through cleaning in place, without disassembly or cooling down. It is a non-abrasive and non-corrosive cleaning process that does not create secondary waste. Due to kinetic energy, dry ice spreads throughout the cracks eliminating waste which results in improved quality of the final product and prolonged lifespan of the machinery.

Examples

· Casting injection, shell core, permanent and other molds

· Core boxes

· Equipment degreasing

· Electric motors, boxes and installations

· Control panels

· Hydraulics

Foundry

General Equipment Cleaning

Increase the efficiency and lifespan of your equipment while saving time

Dry ice blasting is a fast and safe way to maintain all types of equipment. ICEsonic’s dry ice blasting is a completely dry cleaning process that is safe for all electrical components on your equipment. It allows you to clean in-place without cooldown or disassembly. Dry ice blasting is a non-abrasive, non-conductive cleaning method that is safe for the surface of your equipment. It will not create additional harmful waste.

Recommended Products

Foundry

Operational Equipment Cleaning

Clean machines and electronics during operation to reduce downtime

Dry ice blasting is faster and more effective way of cleaning your operational equipment. ICEsonic dry ice blasting system enables you to remove the buildup from your equipment reducing the risk of breakdown without damaging surfaces. This cleaning method is non-abrasive, does not create secondary waste and is environmentally friendly. It improves preventative maintenance as well as inspection processes. Using ICEsonic dry ice blasting you will note reduction in production downtime and unplanned maintenance.

Recommended Products

Foundry

Weld Line Cleaning

Reduce scrap rates and improve the efficiency of your weld lines

ICEsonic dry ice blasting equipment is used for cleaning automated weld lines to improve efficiency and accuracy by removing resin, smoke, oil, spatter and dampering adhesive buildup from production equipment and auxiliary equipment.

Recommended Products

Foundry

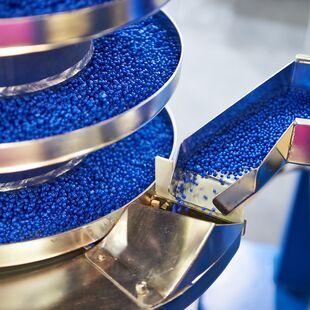

Core Box Cleaning

Eliminate the risk of damage and improve the product quality

ICEsonic dry ice blasting is a fast, effective, and non-abrasive way of cleaning core boxes. Dry ice cleaning can be performed safely while the core box is at operating temperature which saves you time. Also, it doesn’t create secondary waste which means no scraps, no vent clogging, no damages to the core or the tooling. Cleaning core boxes with dry ice leads to noticeable reduction in production downtime and scrape rates.

Recommended Products

Dry Ice Blasting Benefits

Dry ice blasting is the best choice for cleaning tasks without damaging equipment. ICEsonic’s dry ice blasting removes grease, oxides, lubricants, sand, dust, resin, carbon and refractory coating. This cleaning method is non-abrasive and does not produce secondary waste, meaning it is safe for mold vents and rounding mold edges.

· Non-abrasive

· No secondary waste

· No disassembly

· No manual cleaning

· Reduction in downtime

· Cleaning in-place

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.