Textile

Dry ice blasting effectively removes glue and lint from your production equipment

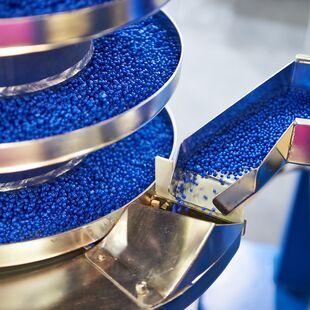

Lint, glue and other residuals generate problems in the textile industry. ICEsonic dry ice blasting system is designed to remove a variety of buildups from textile production equipment. Dry ice blasting doesn’t create secondary waste or moisture enabling you to clean in-place without disassembling your equipment. Non-abrasive properties of the dry ice make dry ice blasting excellent for frequent use without causing damage on production equipment.

Examples

· Tenter machines

· Coating equipment

· Looming equipment

· Conveyors

· Spools

· Glue applicators

Textile

General Equipment Cleaning

Increase the efficiency and lifespan of your equipment while saving time

Dry ice blasting is a fast and safe way to maintain all types of equipment. ICEsonic’s dry ice blasting is a completely dry cleaning process that is safe for all electrical components on your equipment. It allows you to clean in-place without cooldown or disassembly. Dry ice blasting is a non-abrasive, non-conductive cleaning method that is safe for the surface of your equipment. It will not create additional harmful waste.

Recommended Products

Textile

Adhesive Removal

Prolong your equipment lifespan and eliminate time consuming manual cleaning

Dry ice blasting is far superior to the cleaning methods typically used in adhesive removal. It provides you with the ability to drastically reduce downtime. Dry ice weakens and breaks the bond between the adhesive and surface thanks to its low temperature (-79°C). It is a dry, non-abrasive and non-conductive cleaning process, making it the best option for regular cleaning of the equipment.

Recommended Products

Textile

Operational Equipment Cleaning

Clean machines and electronics during operation to reduce downtime

Dry ice blasting is faster and more effective way of cleaning your operational equipment. ICEsonic dry ice blasting system enables you to remove the buildup from your equipment reducing the risk of breakdown without damaging surfaces. This cleaning method is non-abrasive, does not create secondary waste and is environmentally friendly. It improves preventative maintenance as well as inspection processes. Using ICEsonic dry ice blasting you will note reduction in production downtime and unplanned maintenance.

Recommended Products

Dry Ice Blasting Benefits

Dry ice blasting saves time because it does not require cooldown of the equipment or disassembly. Reduction in cleaning time will cause reduction in downtime of your production. Non-abrasive properties of dry ice allow frequent maintenance without damage to the production equipment. Dry ice blasting does not require additional chemicals making it environmentally and employee safe.

· Non-abrasive

· Non-conductive

· Doesn’t create secondary waste

· Reduction in production downtime

· No cooldown required

· No additional chemicals

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.