Oil and Gas

Successfully remove bitumen, dirt, soot, grease and oil buildup in oil and gas facilities

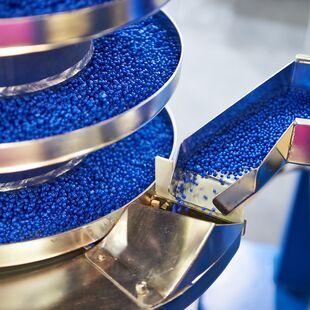

Dry ice blasting is a perfect solution for eliminating buildup from your oil and gas industry equipment because it is non-abrasive, non-flammable and non conductive. The process uses dry ice pellets at −79 °C and upon impact pellets freeze and detach the contaminants from the surface. Due to kinetic explosion the pellets rapidly change from solid to gas (sublimation) leaving the surface dry and clean. Safely and without damage, ICEsonic dry ice blasters will remove bitumen, oil and other accumulation from heat exchangers, motors, pumps, vessels, pipelines and holding tanks.

Examples

· Pipes and Pipelines

· Wellhead equipment

· Remove bitumen and oil

· Production equipment

· Pressure, storage and production vessels

· Heat exchangers

Oil and Gas

Power Generation Equipment Cleaning

Remove buildup and improve the efficiency of your power generation equipment

ICEsonic dry ice blasting effectively removes carbon, grease and other buildup from the equipment and improves megger readings. Dry ice blasting is safe to use on the power generation equipment due to its non-abrasive and non-conductive properties. This cleaning method is used in-place, with no cool down or disassembly required. Dry ice blasting is used to clean aerial coolers, boilers, tubes, radiators, turbines, compressors, motors, generators and other.

Recommended Products

Oil and Gas

Oil Industry

Treated surface is clean, dry, oil free and ready for further treatment

ICEsonic dry ice blasting system helps you maintain your oil and gas equipment by removing oil, bitumen, failed coating, corrosion, soluble salts and chloride. It is used to effectively clean operational equipment and their hard to reach places reducing disassembly. Dry ice blasting does not create secondary waste and enables you to clean in-place. Due to non-abrasive properties of dry ice, this cleaning method does not damage the surface and leaves the surface dry, clean and ready for immediate painting or coating. It is the most efficient way to clean operational equipment, HRSG (heat recovery system generators), turbines, heat exchangers, production and storage vessels, tanks, pipelines, transport vehicles, pipes and pipelines, valves and gauges, oil wellhead equipment and others.

Recommended Products

Oil and Gas

Natural Gas Industry Cleaning

Dry ice blasting can effectively remove deposits and prevent corrosion

ICEsonic dry ice blasting is an effective and safe way of cleaning equipment in the industry of natural gas. It is an effective cleaning method when removing sulfur deposits, ammonia salts and corrosion. Dry ice blasting does not create secondary waste and can be performed in-place reducing downtime. Dry ice blasting can be performed frequently due to its non-abrasive properties and increase the efficiency of your equipment. It can be used on compressors, regenerators, alternators, HRSG, heat exchangers and other.

Recommended Products

Oil and Gas

Operational Equipment Cleaning

Clean machines and electronics during operation to reduce downtime

Dry ice blasting is faster and more effective way of cleaning your operational equipment. ICEsonic dry ice blasting system enables you to remove the buildup from your equipment reducing the risk of breakdown without damaging surfaces. This cleaning method is non-abrasive, does not create secondary waste and is environmentally friendly. It improves preventative maintenance as well as inspection processes. Using ICEsonic dry ice blasting you will note reduction in production downtime and unplanned maintenance.

Recommended Products

Dry Ice Blasting Benefits

ICEsonic dry ice blasting equipment is portable and designed to be used in place, in this way disassembly is minimized as well as the preparation time. Due to non-abrasive properties of dry ice, this cleaning method does not create secondary waste and costs of waste disposal are reduced. ICEsonic dry ice blasting system is an effective way of cleaning, maintaining and improving efficiency of upstream, midstream and downstream equipment.

· Non-abrasive

· No additional chemicals

· Doesn’t create secondary waste

· Clean in-place

· Environmentally and employee safe

· Reduction in production downtime

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.