Pharmaceutical

Effective cleaning that reduces scrap rates and increases product quality

Dry ice blasting is a completely dry process and ideal for the pharmaceutical industry. Water-based cleaning methods can cause bacteria growth and therefore health risks. Dry ice is an approved medium by the FDA, and is non-toxic, non-hazardous and inhibits mold & bacteria growth. Due to non-abrasive properties of dry ice, the process preserves molds and tooling which results in significant reduction of tooling replacement costs. ICEsonic provides dry ice blasting machines for in-place cleaning. This cleaning method grants you faster and more effective cleaning that doesn’t create secondary waste.

Examples

· Capsule production machines

· Tablet press machines

· Injection molds

· Conveyor belts

· Emulsifying and coating equipment

· Homogenizers

Pharmaceutical

Rubber Mold Cleaning

Increase the lifespan of your rubber molds and improve product quality

ICEsonic dry ice blasting system enables you to remove the buildup of material and release agents that will cause change in mold geometry. Dry ice cleaning method does not require cooldown of the press or disassembly. This way you can avoid reassembly damages and save time. Non-abrasive properties of dry ice allow frequent maintenance and longer tooling lifespan, at the same time the scrap rate is reduced. Dry ice blasting is a fast and effective cleaning method that reduces cleaning time and labor costs up to 80%.

Recommended Products

Pharmaceutical

Parts Finishing

Gentle yet powerful when you need to remove burrs from molded parts

ICEsonic dry ice blasting provides a solution for a faster, more efficient and safer way to do parts finishing. Dry ice blasting effectively removes burrs from molded parts. Dry ice blasting ensures that the geometries of the part are maintained, thanks to dry ice blasting being non-abrasive and not leaving any additional residue.

Recommended Products

Pharmaceutical

Operational Equipment Cleaning

Clean machines and electronics during operation to reduce downtime

Dry ice blasting is faster and more effective way of cleaning your operational equipment. ICEsonic dry ice blasting system enables you to remove the buildup from your equipment reducing the risk of breakdown without damaging surfaces. This cleaning method is non-abrasive, does not create secondary waste and is environmentally friendly. It improves preventative maintenance as well as inspection processes. Using ICEsonic dry ice blasting you will note reduction in production downtime and unplanned maintenance.

Recommended Products

Pharmaceutical

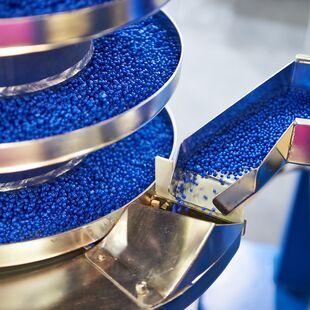

Plastic Injection Mold Cleaning

Increase the quality and lifespan of your plastic injection molds

ICEsonic dry ice blasting is a fast, effective and non-abrasive way of cleaning. Due to the dry ice blasting technology, mold cleaning can be performed on an operational mold press at operating temperatures. It is used to clean extruder screws, dies and casts, ovens, mixers, molds and other plastic injection equipment. Dry ice blasting will improve operational efficiency, quality parts and reduce costs.

Recommended Products

Dry Ice Blasting Benefits

Dry ice blasting enables you to thoroughly clean complex cavities and vents of medical molds. This cleaning method quickly removes burrs from finished parts. ICEsonic’s dry ice blasting system improves product consistency, allows you to clean in-place and decrease downtime.

· Non-abrasive

· No secondary waste

· No disassembly

· No manual cleaning

· Reduction in downtime

· Reduction of cleaning costs

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.