Clean Faster With Dry Ice Blasting

Contact us to find out more

Contact UsDry Ice Blasting

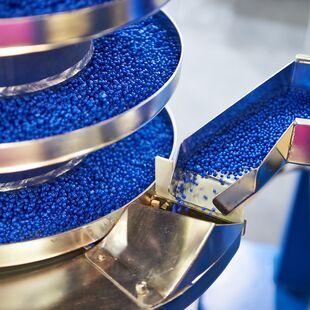

Dry Ice Production

Trusted Worldwide

ICEsonic is trusted by some of the world’s most reputable brands. We partner with businesses from around the world to help them save time and money.

Why Choose ICEsonic?

Unmatched Quality

With over 25 years of experience in the industry, ICEsonic has established itself as a leading manufacturer of dry ice blasting machines, known for unparalleled quality. Our machines are built using the highest-grade materials and undergo rigorous testing to ensure their durability and reliability. We pride ourselves on delivering top-notch performance, allowing our customers to achieve exceptional cleaning results. By investing in an ICEsonic dry ice blasting machine, you can trust that you are getting a product of unmatched quality that will meet your cleaning needs effectively and efficiently.

Industry Leaders

ICEsonic has established itself as an industry leader in the field of dry ice blasting. Our extensive experience and expertise have enabled us to develop cutting-edge technology that meets the evolving needs of various industries. We work closely with our customers to understand their specific requirements and deliver customized solutions that cater to their unique cleaning challenges. As industry leaders, we stay ahead of the curve by continuously innovating and staying up to date with the latest advancements in dry ice blasting technology. When you choose ICEsonic, you are partnering with a company that is at the forefront of the industry, offering reliable and industry-leading dry ice blasting machines.

Cost Effective

At ICEsonic, we understand the importance of cost-effectiveness for our customers. Our dry ice blasting machines are designed to provide optimal cleaning efficiency, reducing labor and cleaning time. Additionally, the use of dry ice pellets eliminates the need for water, chemicals, or additional cleaning agents, resulting in significant cost savings. We strive to offer our customers the best value for their investment, providing them with cost-effective solutions that deliver exceptional cleaning performance. When you choose an ICEsonic dry ice blasting machine, you can be confident that you are making a smart financial decision.

A Global Presence In Every Industry

Learn how ICEsonic is being used in your industry

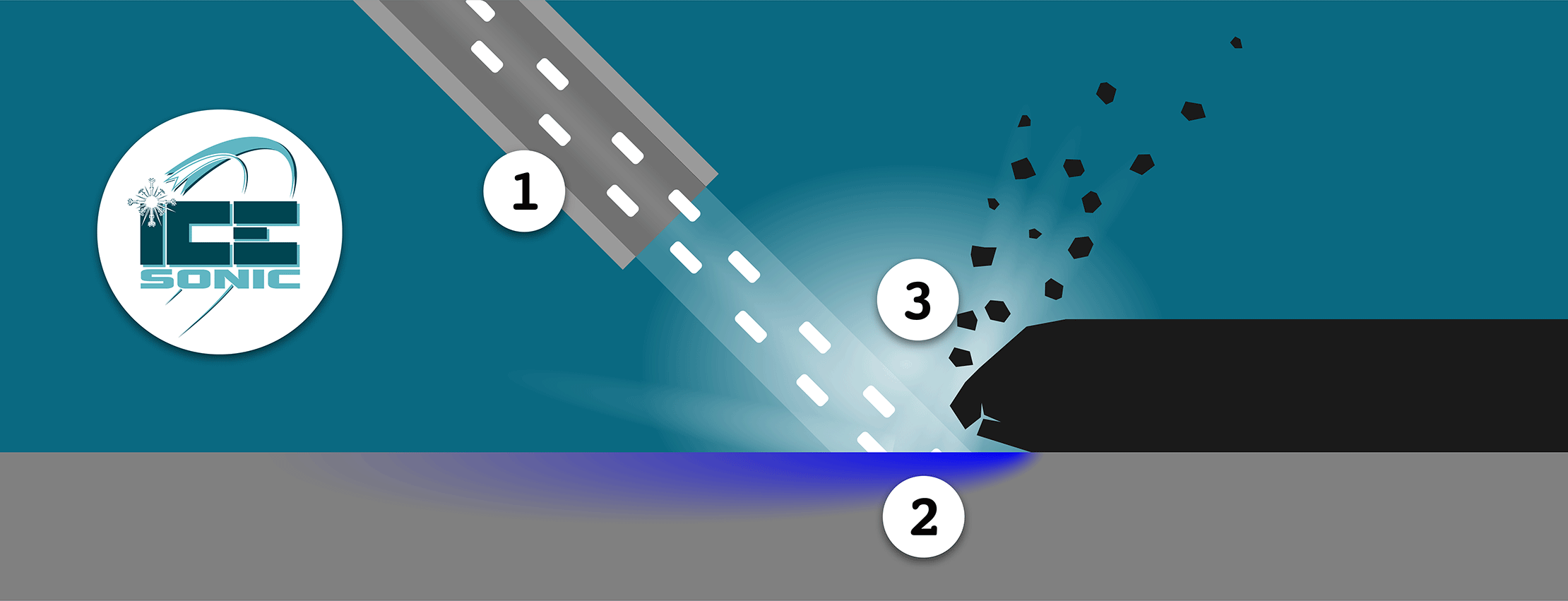

What is Dry Ice Blasting?

Dry ice blasting is a form of cleaning where pellets of dry ice are propelled at extremely high speeds towards a contaminated surface. This is similar to sandblasting, plastic bead blasting, or soda blasting. The difference is that dry ice blasting does not create secondary waste or chemical residues, and is non-abrasive, non-conductive, non-flammable, and non-toxic. It reduces or eliminates employee exposure to chemicals, and is an environmentally friendly cleaning method that is approved by the FDA, EPA, and USDA.

Dry ice blasting propels dry ice pellets at high speeds towards a contaminated surface, and upon impact, the pellets detach the contaminant from the surface, and rapidly change from solid to gas leaving nothing behind. Because of the rapid change, only a small amount of force is transferred to the surface, which leaves the surface with no abrasion. The dry ice pellets are very cold at −78 °C or −108 °F, and on impact causes thermal shock to the contaminant on the surface, which weakens the contaminant, and because the pellets of dry ice go through a rapid change from solid to gas, this causes microscopic shock waves to detach and remove the contaminant from the surface. This leaves you with a very clean, dry, and intact surface with no residue.

This is truly cutting edge technology in the cleaning industry, and with ICEsonic you will get dry ice blasting products with 25 years of expertise behind them. We have developed a wide range of products from light duty work to heavy duty work, and an even wider range of accessories so that our customers can have exactly what they need to solve their cleaning problems. We will happily consult you on the best way to solve your problem.

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.